Por {0}

Por {0}

Full customization

Full customization Design-based customization

Design-based customization Sample-based customization

Sample-based customization Cooperated suppliers (21)

Cooperated suppliers (21)

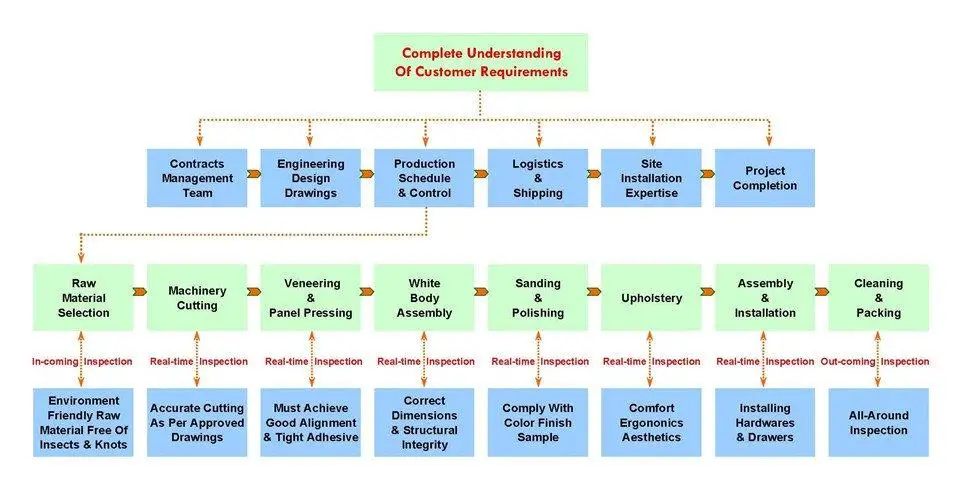

Project Management & Quality Assurance

Whether it is individual bespoke furniture pieces or a-million-dollar fit out of hotel projects, our devotion to the customer remains the same and it will be treated with good care by professionals.

As for project execution, our talented project managers streamline the whole process from shop drawings to after-sales services:

1) Issuing detailed drawings and make sure that all details are correct as per client's requirements or making notes if we need modify some details to suit the manufacturability.

2) Coordinating with the client on the technical details to get the drawings approved for prototyping purpose.

3) Hosting client's inspection on prototypes.

4) Issuing formal prototype inspection report for production purpose.

5) Hosting the pre-production meeting in order to make sure all production depts. acknowledge the detailed requirements & slight modification from prototypes.

6) Finalizing the fabric/leather usage information for client to order COM fabrics/leathers.

7) Coordinating with the client on open issues popping out during production.

8) Coping with client to set up delivery schedule and deal with after-sales services.

As for actual production, we have a proven and well defined approach to monitor our manufacturing practice. We employ experienced supervisors to keep stringent check during each production process from raw material to final packing:

1) In-coming inspection on MDF/plywood panels (E0 grade), glues/paint environment friendly), hardware (function, durability), etc.

2) On-line inspection on veneers (texture consistency, color variation, scratch, over-sanding), solid timber frames (moisture, crackles, knots, damage).

3) Real-time inspection on veneering process and wood cutting/carving process to get good job done.

4) Ensuring every assembled item is completely complied with client's approved drawings.

5) Benchmarking client's approved color samples for polishing purpose.

6) Making sure the packages are concisely marked and clearly labeled, especially for fitted joinery knock-down products.

7) Using plywood boxes to protect fragile products for LCL sea shipment & air shipment;

In summary, we care for the clients from the very beginning to completion of each project, incl. FF&E schedule, specs, pricing, tech communication, prototyping, sourcing, production, COM fabrics/leathers, delivery, after sales service, etc. We are proud to advocate our mentality:

1) Clear, concise & complete communication;

2) Positive, efficient & real-time coordination;

3) Detail-oriented & result-based project management.

![]()

![]()

![]()

![]()

![]()